What Is DPI (Dots Per Inch)? A Technical Overview

DPI (Dots Per Inch) is a unit used to measure dot density, primarily in the printing industry. It specifies how many individual ink dots a printer can place within one linear inch (2.54 cm). Higher DPI values typically indicate finer detail and improved print quality.

These ink dots ("dots") are created using the printer's base colors (e.g., Cyan, Magenta, Yellow, and Black in CMYK systems). The color palette is limited (usually 4 to 6 colors). Printers adjust the perceived color and tonal intensity by varying dot size and applying halftoning techniques (dot placement within a localized grid).

DPI vs. PPI: A Common Misconception in Image Resolution

While technically distinct, the term DPI is often incorrectly used interchangeably with PPI (Pixels Per Inch), especially in digital photography, scanning, and image editing. Even in professional contexts, DPI is frequently referenced when PPI is actually intended. Understanding the difference is essential: DPI refers to printer dot resolution, whereas PPI refers to the pixel density of a digital image.

Key Characteristics of DPI in Printing

The following characteristics define DPI in the context of print technology:

- Individual print dots can vary in size (unlike pixels, which are fixed).

- Only a limited number of base ink colors are used per dot (e.g., 4–6 in inkjet printing).

- Multiple smaller print dots are typically required to reproduce the color of a single digital pixel (via halftoning).

- Example: A 1200-DPI printer using a 6×6 dot grid to simulate one pixel effectively reproduces image data at just 200 PPI (1200 / 6 = 200).

DPI is relevant to output devices that generate images by rasterizing a limited number of base colors:

- Laser printers

- Inkjet printers

- Offset printing presses

In high-quality prints, these dots are no longer discernible to the naked eye and visually merge into a continuous tone image.

How Do You Calculate DPI?

To calculate the DPI of a print or scan, divide the number of dots (or pixels, in the case of scans) by the length in inches. If the length is provided in metric units (mm or cm), convert it to inches first (1 inch = 25.4 mm).

Formula

Use the following formula or the DPI Calculator:

DPI = Pixelslength(inches) = Pixelsin = Pixels × 25.4mm(1 in)length(mm)

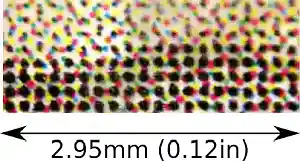

Sample Calculation for the Above Image:

The image displays 20 print dots (often referred to as "pixels" in this context) across a measured length of 0.12 inches.

DPI = Pixelslength(inches) = 20 Pixels0.12 in = 167 DPI

The Crucial Difference Between DPI and PPI

To summarize: Digital devices such as cameras, scanners, monitors, and projectors use pixels. Their resolution is expressed in PPI (Pixels Per Inch). In contrast, printers work with physical ink dots, and their resolution is defined by DPI (Dots Per Inch).

Although the formula used is similar, these are fundamentally different technologies. The image below illustrates this distinction visually:

Comparison: PPI describes digital pixels, while DPI describes physical print dots.

Recognizing the difference between DPI and PPI is essential for producing high-quality results in both digital and print workflows.

Print Formats with Recommended Resolution

| Standard DPI | Typical Application | Example Format (inches) | Pixels (W × H) |

|---|---|---|---|

| 20 | LED walls, large-format outdoor advertising | 96 x 144 in | 1920 × 2880 |

| 30 | Projection screens on stages, trade show construction | 48 x 72 in | 1440 × 2160 |

| 50 | Low-res displays, old e-book readers, B/W scan | 4 x 6 in | 200 × 300 |

| 72 | Large posters, screen display (classic) | 24 x 36 in | 1728 × 2592 |

| 100 | Advertising / trade show wall / XXL print | 30 x 40 in | 3000 × 4000 |

| 150 | Large format posters, gallery | 18 x 24 in | 2700 × 3600 |

| 200 | Posters, rollups | 16 x 20 in | 3200 × 4000 |

| 250 | Art prints, exhibition prints | 11 x 14 in | 2750 × 3500 |

| 300 | Photo printing, brochure, magazine | 4 x 6 in | 1200 × 1800 |

| 400 | Text printing (laser printers), line graphics | 8.5 x 11 in (US Letter) | 3400 × 4400 |

| 600 | Photo scanners, high-quality color prints | 4 x 6 in | 2400 × 3600 |

| 1200 | Fine prints, line drawings, microtext | 2 x 2 in | 2400 × 2400 |

| 2400 | Slide scan, archival scan, repro (35mm) | 0.94 x 1.42 in | 2256 × 3408 |

| 3200 | Film scanner (35mm), high-quality repro | 0.94 x 1.42 in | 3008 × 4544 |

| 4000 | Archiving of slides / 35mm film | 0.94 x 1.42 in | 3760 × 5680 |

| 4800 | Flatbed scanners (max. optics / 35mm) | 0.94 x 1.42 in | 4512 × 6816 |

| 8000 | Offset plate exposure, repro studio | 0.5 x 0.5 in | 4000 × 4000 |

The Development and Significance of DPI (Dots Per Inch)

Introduction

DPI, or "Dots Per Inch", represents the number of dots per inch and is a measure of resolution and detail in both printing and display technology. The following sections outline the historical development and significance of DPI in various technological contexts.

1. Early Developments in Printing Technology

In the 1970s, laser printers began to emerge, enabling higher print resolutions. In 1976, IBM introduced the IBM 3800, which achieved a resolution of 240 DPI and was designed for use in data centers. Shortly thereafter, Xerox followed in 1977 with the Xerox 9700, which for the first time offered the ability to load various fonts and print high-quality documents.

2. Introduction of DPI in Computer Monitors

With the advent of personal computers in the 1980s, DPI also became relevant for monitors. Apple set a standard resolution of 72 PPI (Pixels Per Inch) on its Macintosh computers to ensure consistency between screen and print output. Microsoft, on the other hand, chose a standard resolution of 96 PPI for Windows to achieve better readability on the monitors common at the time.

3. Developments in Computer Graphics

Computer graphics evolved in parallel with hardware. Raster graphics, which consist of pixel grids, depend on resolution, with quality determined by the number of dots per inch (DPI). Vector graphics, however, use mathematical equations to represent shapes and are resolution-independent, allowing for lossless scaling.

4. Distinguishing Between DPI and PPI

It is important to distinguish between DPI and PPI. While DPI refers to the number of print dots per inch in the printing process, PPI represents the number of pixels per inch on digital screens. Both measures affect the perceived sharpness and quality of images, but they are used in different contexts.

5. Modern Developments and Challenges

With the introduction of high-resolution displays, such as Apple's Retina displays, pixel density increased dramatically. This posed new challenges for software developers, as applications had to be optimized for various DPI values to ensure a consistent user experience. Consequently, Microsoft introduced DPI scaling mechanisms in Windows to adapt applications to different pixel densities.

6. The Future of DPI

Technological Advances: New printing methods and inks (such as single-pass inkjet, special inks like AQUAFUZE) enable high quality and efficiency without necessarily requiring extremely high DPI values. Other factors, such as droplet size, ink adhesion, and sustainability, are becoming increasingly important.

DPI Remains Relevant, but More Nuanced: The 300-DPI standard for high quality remains in place, but is now complemented by application-specific requirements (e.g., lower DPI for large formats, asymmetric DPI values).

Software and AI: Intelligent image processing and AI can improve perceived print quality even at moderate DPI values and streamline data processing.

Sustainability: The focus is also shifting toward more resource-efficient methods, where an excessively high DPI value (and the associated higher ink consumption/time) may not always be the objective.

In Summary: DPI is still an important technical parameter, but its sole dominance as a quality benchmark is being relativized by new technologies, software intelligence, application requirements, and sustainability considerations. Efficiency, versatility, and environmental friendliness are increasingly becoming equally, if not more, important factors.

Conclusion

Technological Advances: New printing methods and inks (such as single-pass inkjet, special inks like AQUAFUZE) deliver high quality and efficiency without necessarily requiring extremely high DPI values. Other factors, such as droplet size, ink adhesion, and sustainability, are gaining in importance.

DPI Remains Relevant, but More Nuanced: The 300-DPI standard for high quality persists, but is supplemented by application-specific requirements (e.g., lower DPI for large formats, asymmetric DPI values).

Software and AI: Intelligent image processing and AI can enhance perceived print quality even at moderate DPI values, and streamline data processing.

Sustainability: The focus is shifting toward more resource-efficient methods, where an excessively high DPI value (and the resulting higher ink consumption/time) may not always be the objective.

In Summary: DPI is still an important technical parameter, but its sole dominance as a marker of quality is being challenged by new technologies, software intelligence, application requirements, and sustainability considerations.

Final Thought: The development of DPI reflects technological progress in printing and display technology. A thorough understanding of DPI and its history is crucial for creating and presenting high-quality visual content across various media.

Sources